We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Hand Soldering with Nitrogen in Electronics

What is the difference between Nitrogen and Oxygen when soldering in electronics?

Oxygen molecules will react and bond with the molecules at the surface of a metal to form a layer of metal oxides called, “oxidation” while Nitrogen will not.

Rust is an extreme example of oxidation. Rust is what happens when a metal such as iron, is exposed to oxygen and water.

What is oxidation when soldering in electronics?

By definition, oxidation is a chemical process by which an ionic chemical reaction occurs at the surface of a metal in the presence of oxygen.

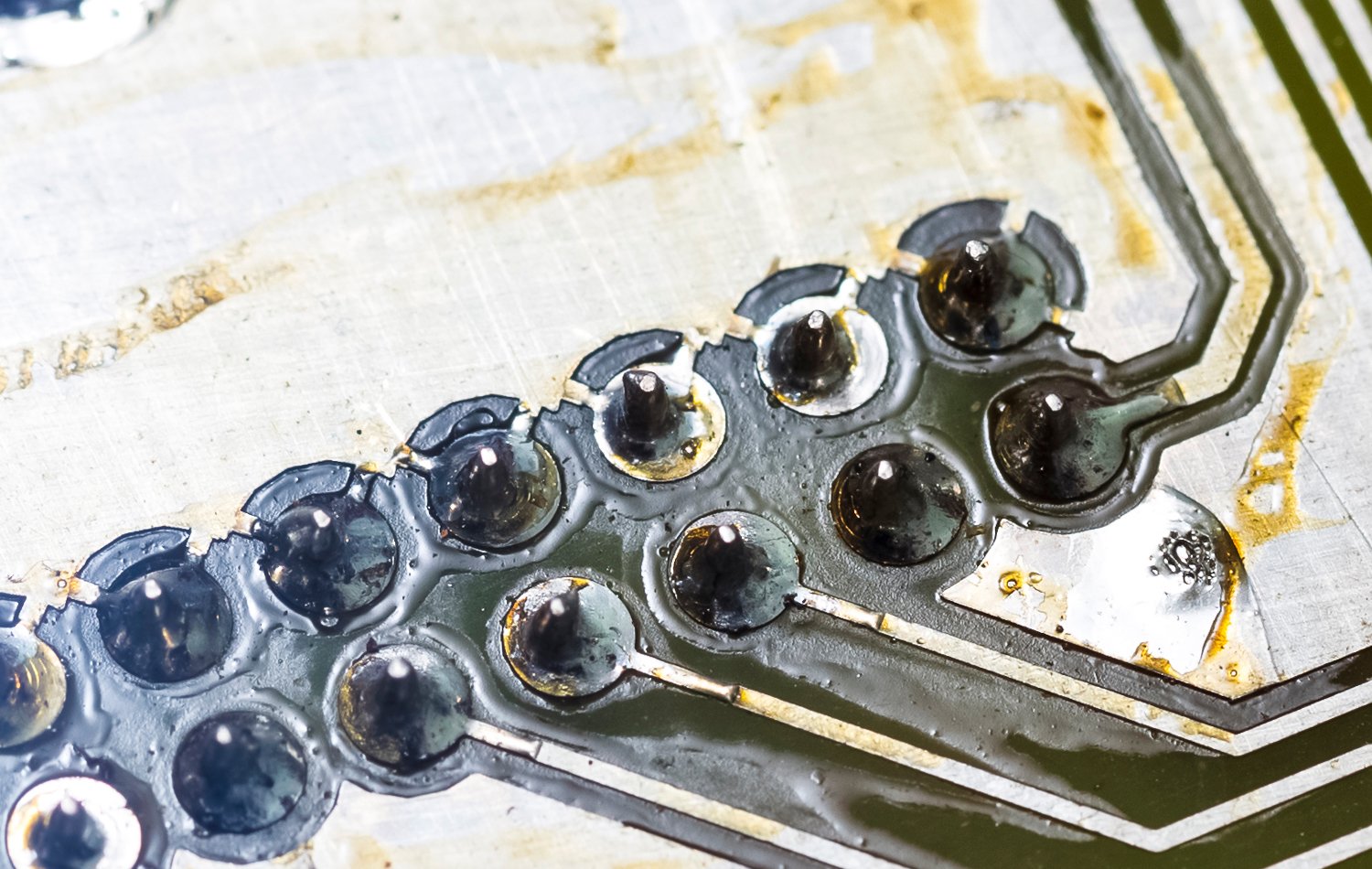

In electronics, the oxidation process occurs when printed circuit boards and component leads are exposed to the air for a prolonged period of time. Add elevated temperatures to the mix and the oxidation rate is amplified.

But oxidation is not confined to just circuit boards and component leads, it is also detrimental to soldering tools and the soldering process, including the wire solder used, namely Lead-Free.

Lead-Free solder is mostly used in soldering electronics today, and like metals, it also oxidizes with exposure to oxygen in the air.

Solder, especially lead-free, does not wet (adhere to) oxidized metals very well, therefore, a flux is needed to remove the oxidation from the metal surface during the soldering process. As a result, stronger, more aggressive fluxes are typically used.

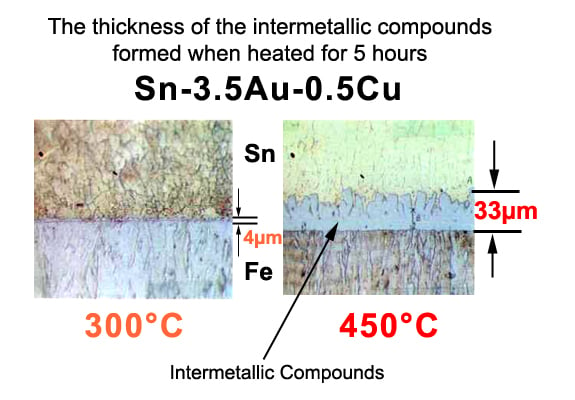

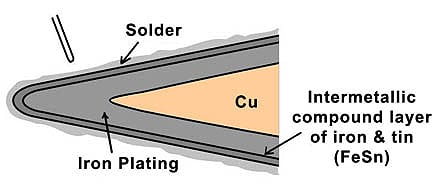

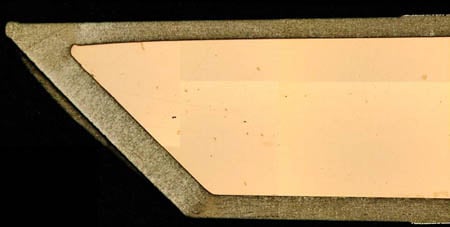

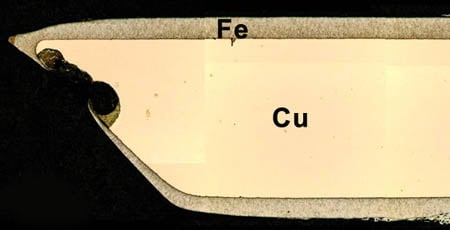

The alloy composition of Lead-Free solder is mostly tin, and when this tin comes in contact with a hot, iron-plated soldering iron tip, oxidation of the tip occurs and an inter-metallic compound forms that dissolves the iron plating on the tip more quickly, thus shortening the tip life.

To add misery to the oxidation problem, if the soldering iron tip is not cleaned regularly after use, it will not only oxidize, it will quickly lose its ability to wet with the solder and eventually become useless and need to be replaced.

Good grief, you say.

But wait, we have a solution — Nitrogen!

How does Nitrogen solve the oxidation problem?

Again, Nitrogen is an inert (non-reactive) gas that will not react with metals. Therefore, when utilized with hand soldering in electronics, it helps to prevent and protect the solder, the immediate area to be soldered, and the soldering iron tip from oxidation.

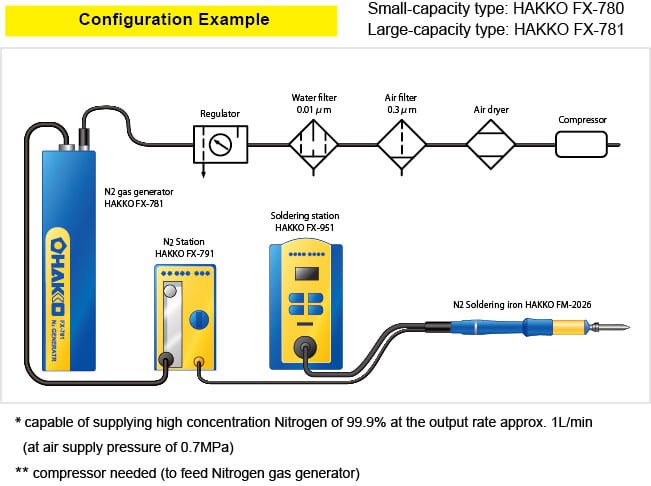

HAKKO has a Nitrogen soldering system that is ideal for lead-free hand soldering applications.

The HAKKO FM-2026 kit (P/N: FM206-KIT) includes a Nitrogen Controller to control the flow of nitrogen (P/N: FX791-01) and a N2 soldering iron handpiece (P/N: FM2026-01).

How does it work?

The FX-791 Controller delivers N2 gas to the N2 FM-2026 soldering iron handpiece through a 3mm tube (P/N: B3022). The N2 gas then travels to the soldering iron tip enclosure where it is heated as it passes along the soldering iron tip. As the gas exits the nozzle, a preheating effect takes place at the soldering area and oxygen is displaced there at the same time.

HAKKO N2 Compatible Handpieces *

HANDPIECE | PART NUMBER | STATIONS USED WITH |

FM2026-02 | ||

FM2031-01 | ||

FM2032-51 | ||

FX8003-81 | ||

FX8802-02 |

*For information on these compatible N2 handpieces visit, HakkoUSA.com

**FM-2032 needs C5038 to C5041 Assembly Nozzle + B5178 Assembly Hose

Preheating with N2 has many benefits. You can:

1. lower the soldering iron tip soldering temperature which will extend the life of the tip

2. use a less aggressive (mild) flux

3. shorten the soldering time which will reduce thermal stress to components and the PCB

4. prevent the oxidation of the soldering iron tip and the soldered joint surface

Where is the source of the Nitrogen?

HAKKO has two compact, desktop Nitrogen Generators that work with the HAKKO FX-791 N2 Controller.

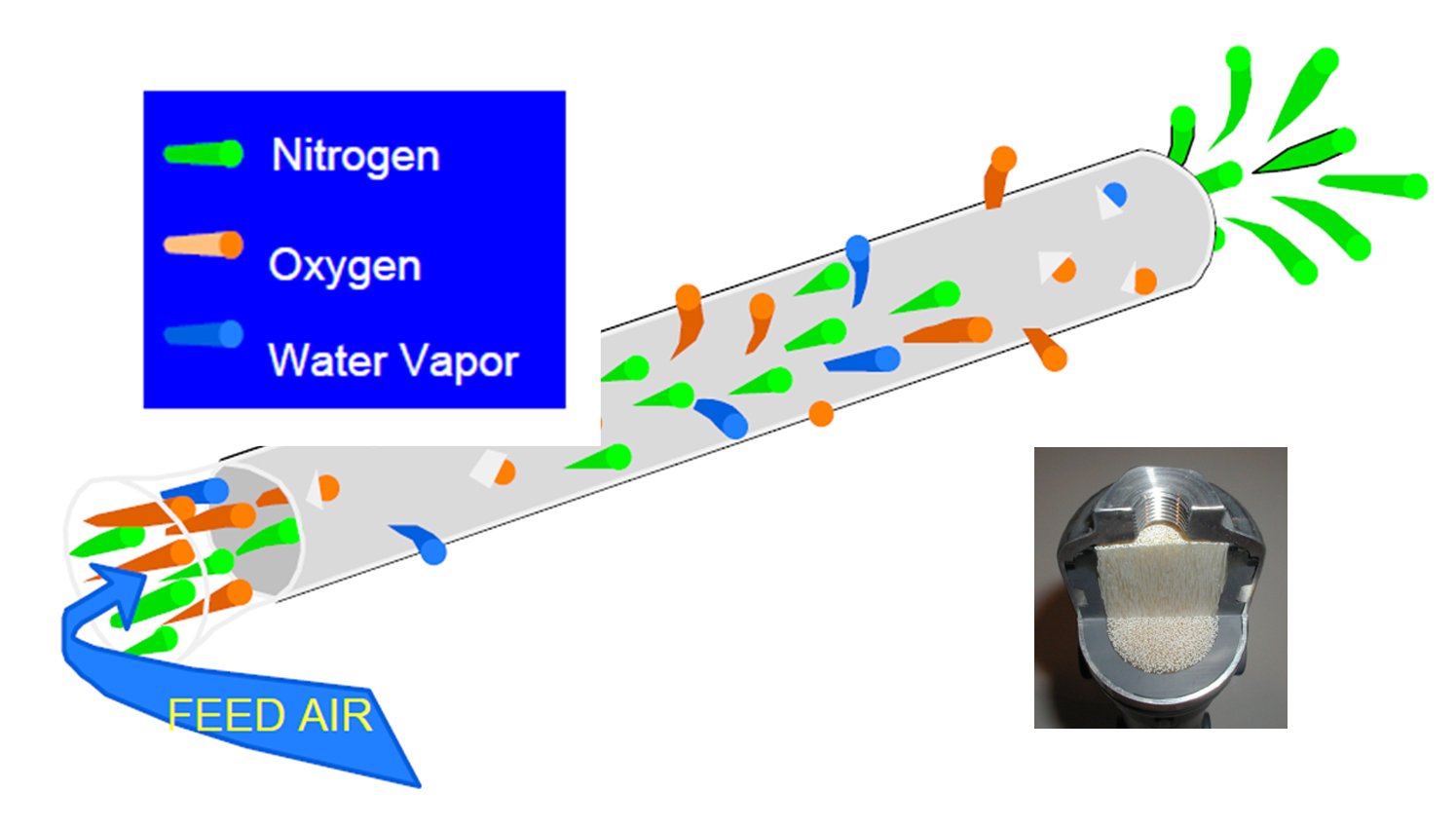

The FX-780 and FX-781 generators are compact, tabletop designs that produce nitrogen from filtered, dry compressed air. Both have a membrane filter that filter the nitrogen from the air with concentration levels as high as 99.9%.

The FX-781 has approximately double the output capacity of the FX-780, producing enough nitrogen gas to accommodate two soldering irons/stations.

The FX-780 and FX-781 Nitrogen generators do not actually “generate” N2 gas but rather separate the N2 from the air. Compressed air is pressure-driven across the membrane filter where the N2 and oxygen are separated, leaving only N2 inside. The nitrogen is then sent to the FX-791 Controller for delivery to the FM-2026 soldering iron handpiece.

The beauty of using the HAKKO tabletop N2 generators is that you can have your own personal supply of nitrogen gas to use on demand whenever and wherever you want. There is no need for a third party nitrogen gas supplier nor any large external tanks.

In conclusion, the benefits of hand soldering with Nitrogen in electronics are:

• greater solder wettability

• greater solder spread factor

• less flux needed

• ability to solder at a lower tip temperature

• longer tip life

• bright and shiny solder joints

Lastly, Nitrogen is not a manufactured gas but extracted from the surrounding air that we breathe. And that’s a good thing.

Thanks for reading. We hope you found this article helpful.

For more information call 1-800-88-HAKKO (42556) or visit us at HakkoUSA.com

-HakkoUSA