We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Why Proper Maintenance is Good

How many of us have neglected the maintenance on our cars, the swimming pool, the lawn, or even our own health, and have paid the consequences for it later?

Was it because we were too busy? Maybe we forgot? Or maybe we simply did not think it was that important?

Regardless of our reasons, the fact we ignored our responsibility to perform the required maintenance cost us time, money and at times perhaps our own health.

Proper maintenance is also essential if we want to ensure our tools and equipment are always operating at 100% efficiency at all times. And proper maintenance on the HAKKO FX-305 Digital Solder Pot is no different.

Daily Maintenance

Wear and tear on the solder pot will vary due to factors such as operating temperatures, the solder alloy being used, and hours of usage. Maintenance of the solder pot should be performed based on how much you use the unit.

General

A very simple yet important maintenance procedure is to simply turn off the unit when not in use for long periods of time.

Keep in mind, using a temperature higher than necessary can accelerate pot deterioration and damage parts that are susceptible to heat. Therefore, use the lowest possible temperature for the work. This obviously will be determined by the melting temperature of the solder alloy being used.

The Pot / Crucible

When cool enough to handle, remove the pot/crucible and visually inspect the following:

• are there any holes in the pot?

• any solder leakage onto the heat insulation plate? The FX-305 has a built-in safety feature where the station will automatically shut off the heaters once solder is detected by a sensor inside the unit.

• any foreign matter collected onto the heat insulation plate?

Make sure you change the orientation of the pot each time you remove it. This will slow any pot deterioration. Rotate the pot/crucible 90 degrees to allow for an even wear on the side walls of the crucible (think similar to tire rotation on a car).

It should be noted that the internal pot temperature can change if it contains too many impurities. Also, the internal pot temperature changes if you replace the pot. Therefore, make sure to change the offset value as needed while monitoring the actual internal pot temperature. You can also input the proper solder alloy type as well as the proper crucible size on the FX-305 to ensure optimum heating profiles.

Using a HAKKO FG-100B/FG-101B thermometer with a temperature probe makes verifying and offsetting the pot/crucible temperature safe and easy (see user manual).

Solder Pot Cover

Lift the safety cover and inspect for any solder stuck to the cover. Remove to prevent any solder debris from falling into the pot, especially when changing the solder type. Make sure to lower the cover when the solder pot is back in use.

Solder

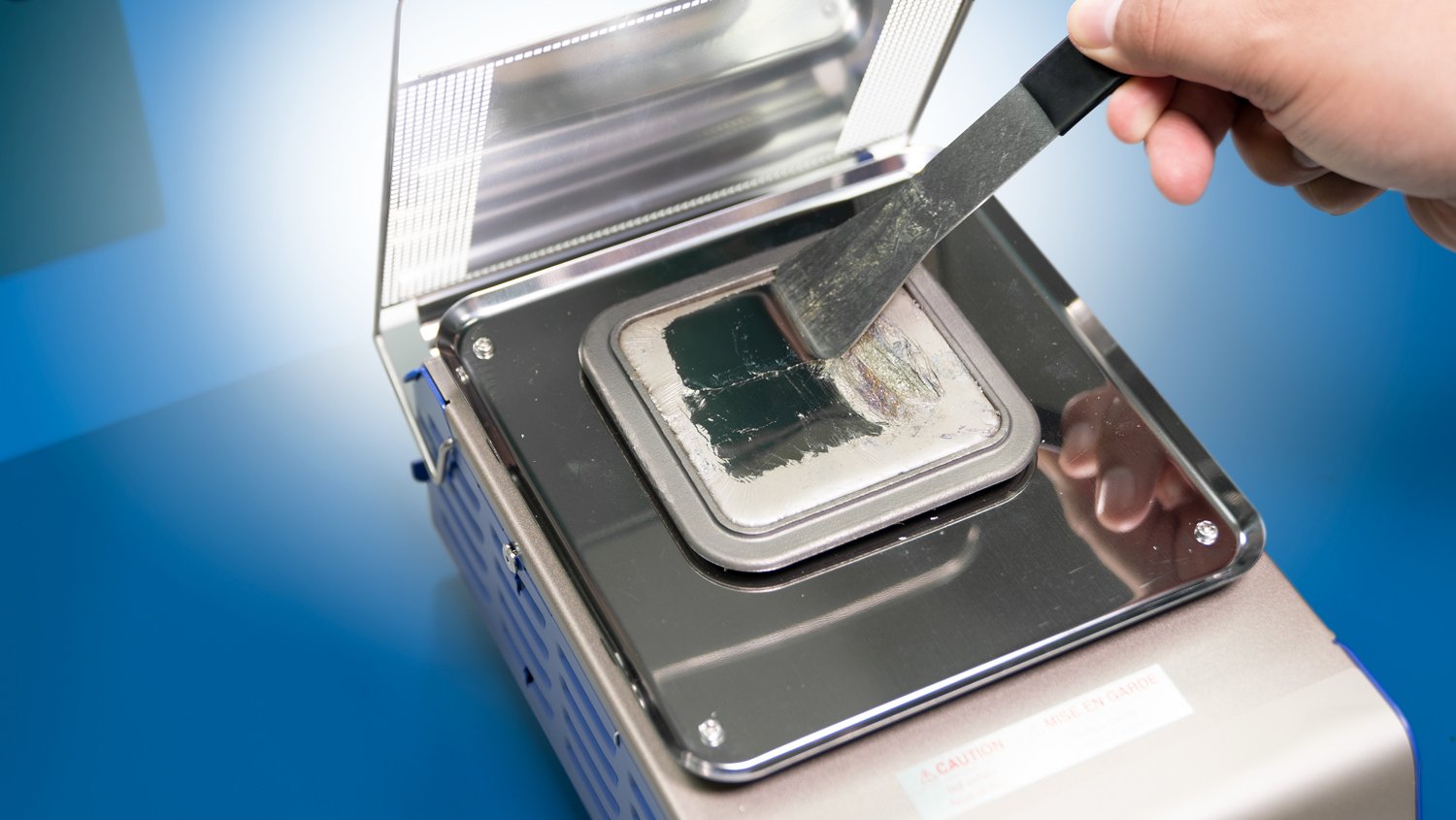

Remove any oxidation or foreign matter in the molten solder with a spatula tool before turning unit off.

Proper maintenance and care will always reward us at the end of the day. It will not only extend the service life of the product, but it will also minimize the downtime and costs. Make maintenance a habit and your HAKKO FX-305 Solder Pot will reward you with a long service life and peace of mind for many years to come.

For additional information, visit us at www.HakkoUSA.com or contact us at 1-800-88-HAKKO (42556) and at [email protected].

-HakkoUSA