We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Intelligent Torque

Drivers

Drivers

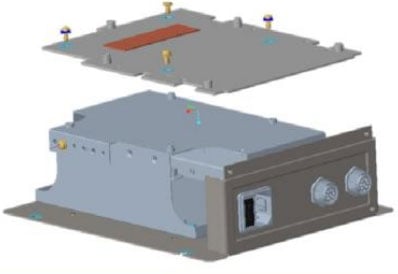

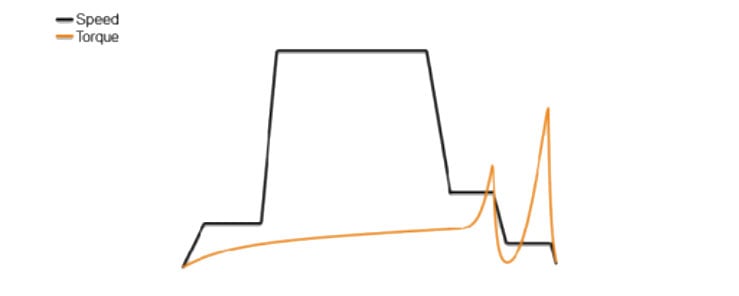

The CHP ATX-12, 30, 50 Intelligent Torque Drivers are premium non-slip grip drivers that work with the ATX Intelligent Torque Controller on programmed pressure and precision. The new CHP ATX Series Smart Servo Fastening System provides high-precision torque and angle-controlled fastening using a high-quality DC brushless servo motor, a high-precision transducer, and high-resolution digital encoder for accurate angle measurement.

Features

& Benefits

Touchscreen

Smart Controller

Dual-Port Available

Network Capability Included

Touchscreen Controller

Graph Data Logging

Dual-Port Available

Network Capable Included

Touchscreen Controller

Graph Data Logging

The new ATX Intelligent Torque Drivers are controlled by a 10-inch, full color LED backlit, LCD touchscreen controller that manages torque speed settings for superior torque control. The controller includes network capability and a user-friendly interface that stores and exports graph data.

Parameters

Sequence

Sources

Results

Controller

Tool

Report

Help

Editing the parameter settings can be accessed through the edit icon.

Tool1

Tool2

All

ID

Parameter Title

| 1 | M5-Standard3.0Nm | ||

| 2 | M4-PrePosition360 | ||

| 3 | M4-Enhance2.0Nm | ||

| ID | 1 | |||

| Standard | ||||

General Settings

Tightening Settings

Loosening Settings

Select the parameter and set the quantity for the sequence.

After choosing a set of parameters and screw quantities, select this area to visually layout the sequence markers as a reference guide.

| ID | 1 | Controller A |

ID

Tool

Parameter Title

Qty

Bit ID

| 1 | Tool 1 | M5-Standard3.0Nm ▼ | 4 ▼ | 0 ▼ | |

| 2 | Tool 1 | M4-PrePosition360 ▼ | 2 ▼ | 0 ▼ | |

| 3 | Tool 1 | M4-Enhance2.0Nm ▼ | 2 ▼ | 0 ▼ | |

Elect to use two tools independently, sequentially, or simultaneously.

Choose one of the following options to switch the tightening parameters or tightening sequence.

No.

Item

| 1 | Manual |

| 2 | Screw Bit Selector |

| 3 | Barcode Scanner |

| 4 | |

| 5 |

Alteration

Synchronization

Tool 1 | Push Start | ||

| Manual | ▼ | ||

| Sequence | Controller A | ||

| Parameter | M5-Standard3.0Nm | ||

kgf.cm

deg

Tool 2 | Push Start | ||

| Manual | ▼ | ||

| Sequence | Controller A | ||

| Parameter | Standard-5.0-M2 | ||

kgf.cm

deg

After completion, review assembly jobs for detailed information on the procedure.

Click on each row to view a detailed look at the tightening results.

Report

Report

Report

Report

| Date/Time | Tool | Final Angle | Tighten Angle | Final Torque | Status | |

| 2023/05/12 12:11:39 | Tool 1 | 0 degrees | 12 degrees | 0.000 kgf.com | ||

| 2023/05/12 12:11:41 | Tool 1 | 0 degrees | 12 degrees | 0.000 kgf.com | ||

| 2023/05/12 12:11:43 | Tool 1 | 0 degrees | 12 degrees | 0.000 kgf.com | ||

| 2023/05/12 12:11:44 | Tool 1 | 0 degrees | 12 degrees | 0.000 kgf.com | ||

| 2023/05/12 12:11:46 | Tool 1 | 0 degrees | 12 degrees | 0.000 kgf.com | ||

| 2023/05/12 12:11:47 | Tool 1 | 0 degrees | 12 degrees | 0.000 kgf.com | ||

| 2023/05/12 12:11:48 | Tool 1 | 0 degrees | 12 degrees | 0.000 kgf.com | ||

| 2023/05/12 12:11:50 | Tool 1 | 0 degrees | 12 degrees | 0.000 kgf.com | ||

Settings

Device

Station

Info

Settings

Settings

Calibration

| Model Name | ECM-SD3-F50S0 | ||

| Max. Speed | 700rpm | ||

| Max. Torque | 50.000kgf.com | ||

| Tool Temperature | 24°C |

| Service Reminder | OFF | ||

| Tightening + Loosening Count | ECM-SD3-F50S0 |

Single & Dual

Ports

The ATX series controller also features an industry-first dual-port controller that can operate two drivers simultaneously or in a user-defined sequence. The dual port controller provides an extra 100W of power to the drivers with all the same benefits. Each fastener parameter is programmable for various combinations of time, torque, rotation angle, and direction. Programmable digital I/O and definable user profiles with password protection to provide process control.

12, 30 & 50

Torque Range

These transducer drivers have an LED status indicator ring, use a 1/4” hex bit, and a torque range of 2.4 to 50 (kgf-cm) with a maximum speed of up to 2000 RPM.

Driver Specifications

| Model | ATX-12 | ATX-30 | ATX-50 |

|---|---|---|---|

| Torque Range | 2.4 - 12 kgf-cm (2.08 - 10.41 lbf-in.) | 6.0 - 30 kgf-cm (5.20 - 26.03 lbf-in.) | 10 - 50 kgf-cm (8.67 - 43.39 lbf-in.) |

| Max Speed (RPM) | 2000 | 1200 | 700 |

| Torque Precision | < ±3% | ||

| Tool Bit Shank | 6.35 mm (0.25 in.) Hex | ||

| Tool Bits Included (50 mm Length) | Phillips #1 - 3.0 mm ø Phillips #2 - 4.5 mm ø | Phillips #2 - 4.5 mm ø Phillips #2 - 6.0 mm ø | 2pcs Phillips #2 - 6.0 mm ø |

| Grip Diameter | 34 mm (1.34 in.) | ||

| Trigger Type | User-Programmable Push/Lever/Both | ||

| Work Light | Integrated White LED - User-Programmable Intensity | ||

| Status Indicator | User-Programmable Yellow/Red/Green | ||

| Dimensions (W x D x H) | 41 x 40 x 272 mm (1.61 x 1.57 x 10.71 in.) | ||

| Weight | 480 g (16.9 oz.) | ||

| Operating Environment | 0 - 40°C (-32 – 104°F) 0 - 90% RH (Non-condensing) | ||

| Enclosure Rating | IP40 | ||

Controller Specifications

| Model | ATX | |

|---|---|---|

| Part No. | ATX-P1 | ATX-P2 |

| Supported No. of Screwdrivers | 1 | 2 |

| Input Voltage | 100 to 240 VAC 50/60 Hz | |

| Power Consumption | 100 W | 200 W |

| Output Voltage | 38 VDC | |

| Continous Output Current (RMS) | 3.7 A / Screwdriver | |

| Max Instantaneous Output Current (RMS) | 15.0 A / Screwdriver | |

| Display | 10.1" TFT LCD Touchscreen | |

| Resolution | 800 x 1280 24-bit RGB | |

| Network Interface | 1 port RJ-45 10/100 Mbps Auto-Detect | |

| Serial Interface | 1 Port RS-232 | |

| 2 Port RS-485 | ||

| HDMI Output | 1 port HDMI 1.4a | |

| USB Host | 1 port USB 2.0 | |

| Digital Input/Output (Per Tool) | 8 - Digital Outputs (150 mA max.) 8 - Digital Inputs (30 VDC max.) | |

| Fastener Definitions | 500 max. | |

| Fastener Sequence Definitions | 500 max. | |

| Dimensions (W x D x H) | 200 x 121.1 x 251.5 mm (7.9 x 4.8 x 9.9 in.) | |

| Weight | 4.02 kg (8.9 lb.) | 4.11 kg (9.1 lb.) |

| Operating Environment | 0 to 40°C (-32 to 104°F) 0 to 90% RH (Non-condensing) | |

| Enclosure Rating | IP20 | |

Electronics

Bringing to life the latest gadgets in entertainment, comfort, and functionality

Aerospace

Allowing engineers, the ability to innovate and reach for the stars

Automotive

Helping create the safety in the vehicles we put on the road for you and others

What We Do

For over 60 years we've provided the manufacturing industry with superior soldering, desoldering, hot, and rework systems, establishing ourselves as a leader in our field. Looking to the future, with innovative minds, we take technology to an all new experience with our robotics and automation.

Defense

Providing tools for applications in defense technologies

Medical

Assisting medical professionals in producing the equipment they require to save lives

Telecommunications

Producing tools for use in telecommunication technologies