We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Solder Pot? Why Use One?

Purpose and Use

When working in electronics, do you “tin” stranded wires with a soldering iron and wished there was an easier method?

Or, does it seemingly take forever to desolder a multi-pin connector from a circuit board when you manually try to desolder one pin at a time?

These are a few reasons why using a soldering pot may be helpful.

What is a Soldering Pot?

Solder pots are primarily used in electronics to “tin” wires or component leads. They can also be used at times to quickly remove components such as multi-pin through hole connectors from a PCB.

For instance, you can:

Solder through-hole components to a printed circuit board

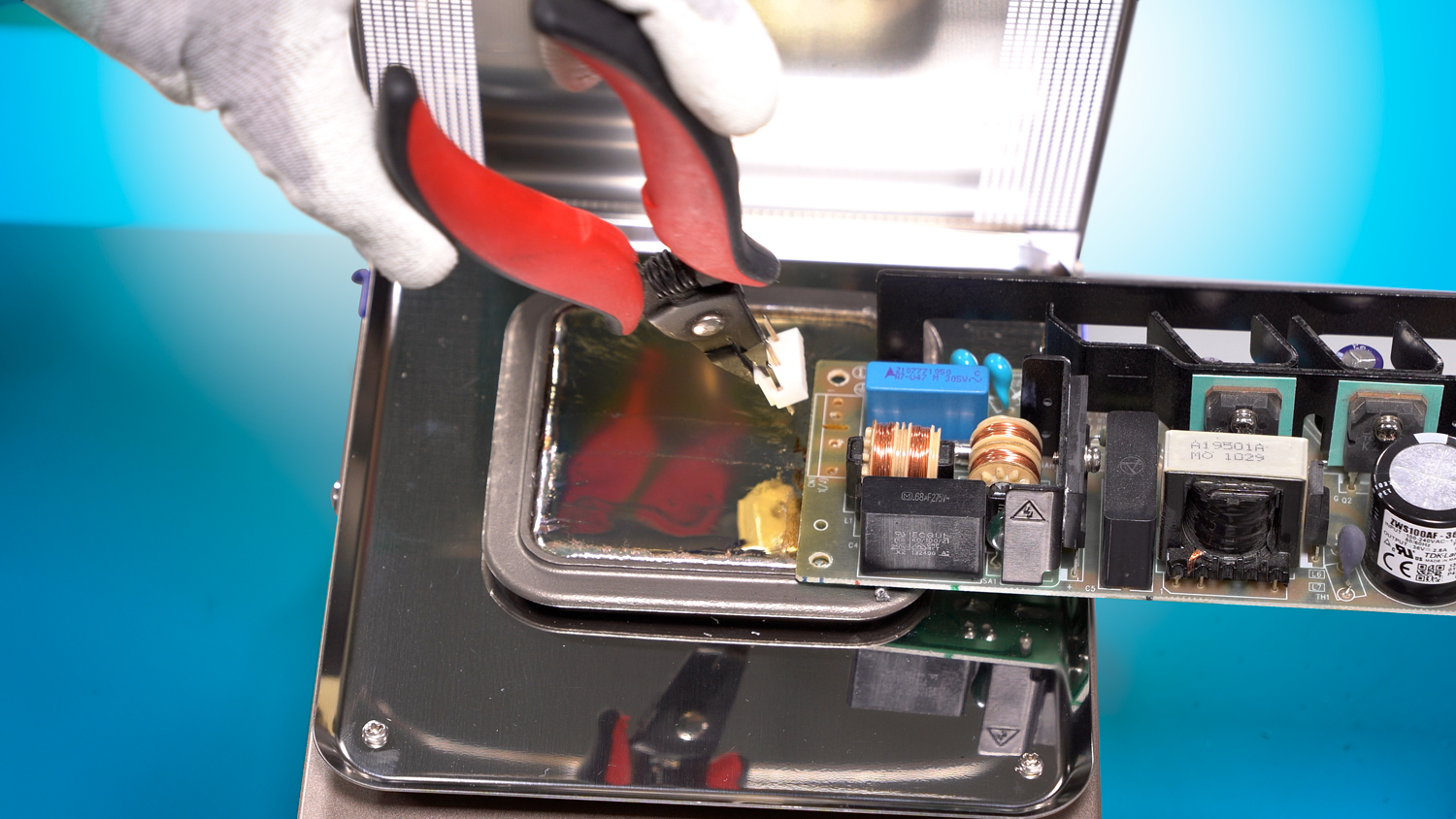

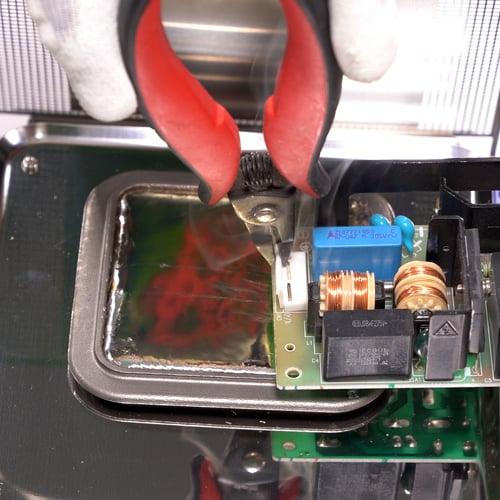

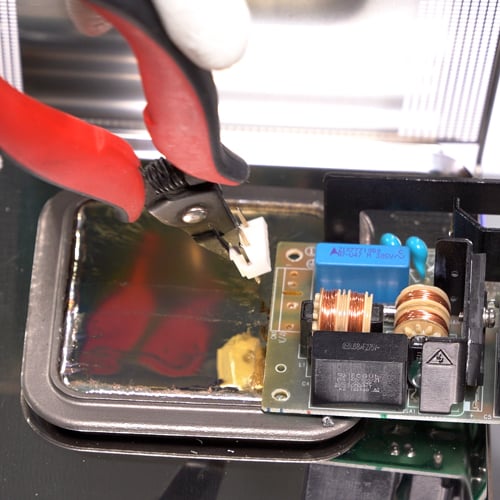

Desolder and remove through-hole components from a printed circuit board

“Tin” stranded wires by simply dipping the strands into the pot/crucible

Portable table-top solder pots typically are in the range of 100W - 600W in power, and consists of a pot/crucible, an adjustable temperature controller (analog or digital), and a heating source/element that will heat up the solder (which is in the crucible) above its melting point.

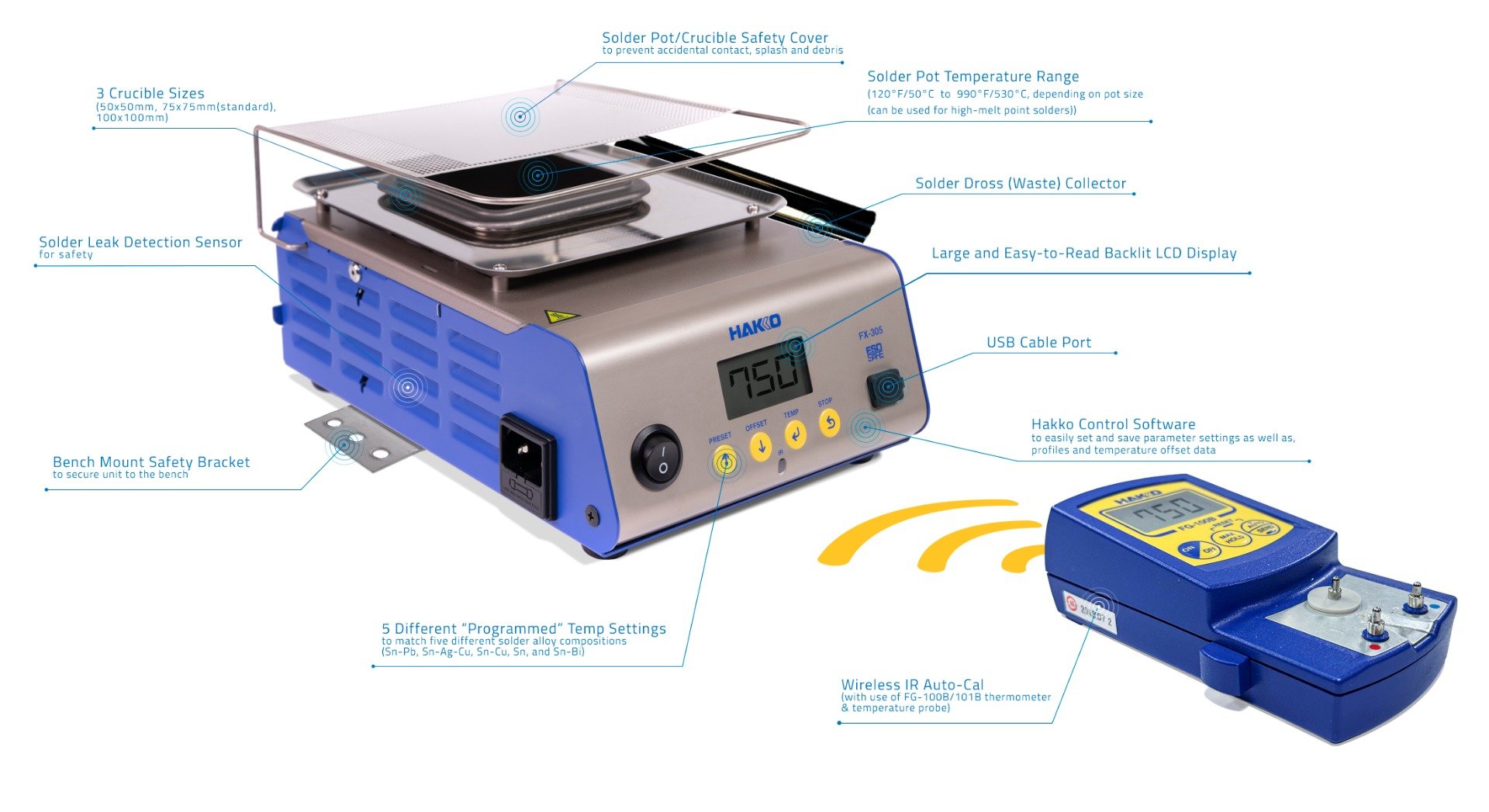

However, not all solder pots are made equally. When it comes to multiple features and benefits, rapid heat up time, and having the capability to select different size crucibles, select different solder alloy types for optimum heating profiles, and computer software controls, there is only one—the HAKKO FX-305 Soldering Pot that has it all.

The HAKKO FX-305 Soldering Pot

Okay, now that we have examined some of the features of the HAKKO FX-305 solder pot, let’s “tin” a stranded insulated wire.

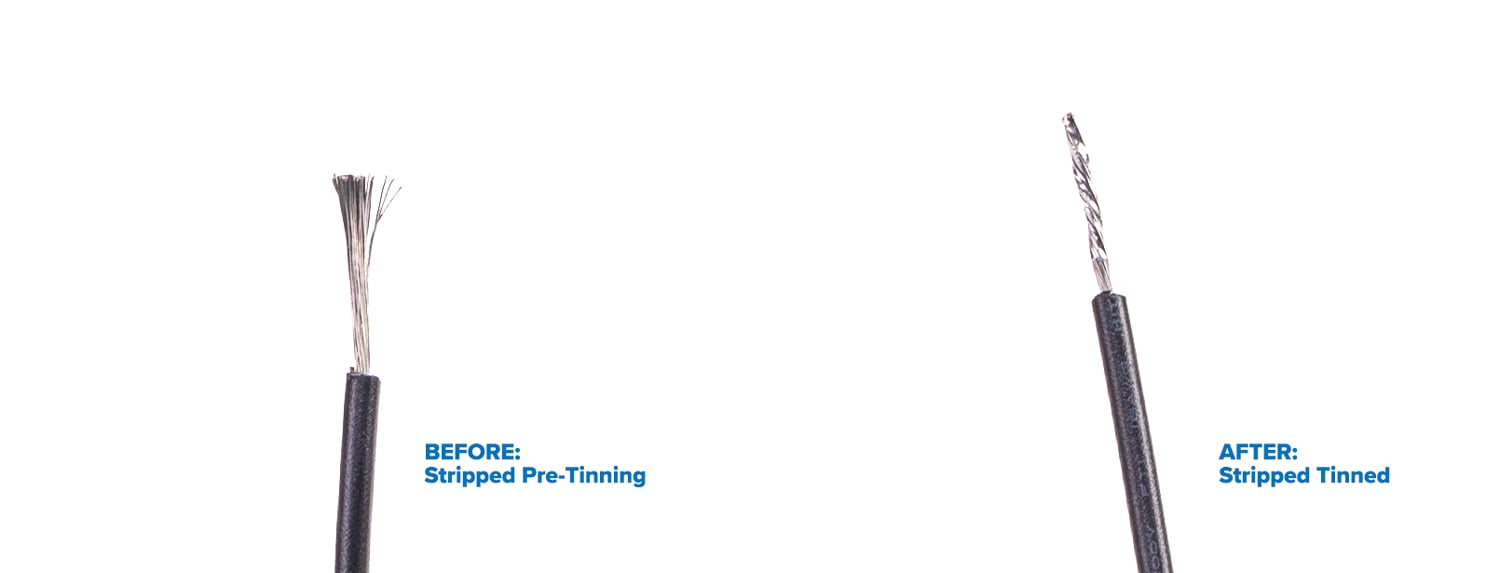

“Tinning” wires and component leads is a standard practice when soldering in electronics.

What is tinning?

“Tinning” is the process of cleaning the metal surface to be soldered (with a flux) and then melting a layer of solder (“tinning”) on that surface. This layer of solder helps prevent oxidation and corrosion of the metal and enhances the wire's connectivity and its ability to transmit electrical current.

“Tinning” also holds the strands together and allows good solderability and good wetting, which means the formation of a uniform, smooth, unbroken coat of solder on the base metal to form one solid connection.

To clean the surface of the metal to be soldered, you will need a soldering flux.

A soldering flux is a chemical cleaning substance that helps remove oxides and other impurities from the surface of electronic parts, wires, and components before and during the soldering process. Flux is your best friend.

Now let’s “tin” a stranded wire.

Turn on the solder pot, select the proper crucible size, and the proper solder alloy being used, then set the temperature for the work. This will be determined by the type of solder alloy being used (the melting point of the alloy composition.)

1. Strip the insulation from the end of the stranded wire with a wire stripping tool

2. Gently twist the multiple strands together with your fingers so they form a tight bond

3.Apply some flux to the strands of wire you want to tin (you may also dip the wires into a small container of flux) , leaving some space from the insulation (the amount of space will vary depending on cables being used). This is important. DO NOT get any flux under the insulation!

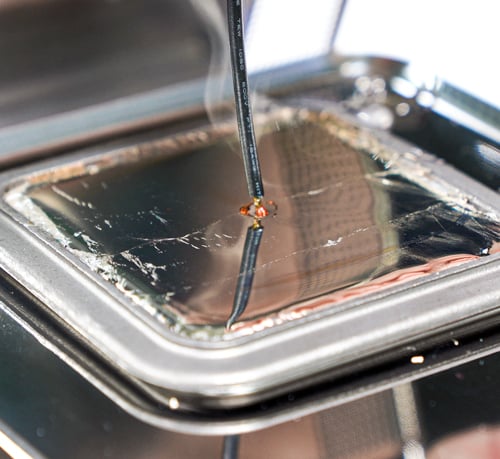

4.Scrape the dross off the surface of the solder in the soldering pot with a spatula tool and remove it from the pot. Dross is that ugly oxidized layer of solder that forms and floats on the surface of the solder.

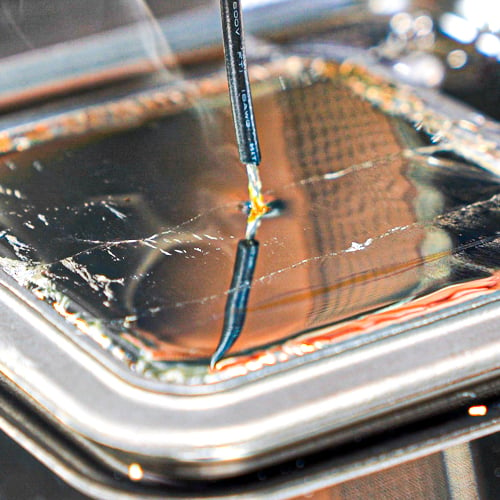

5.Dip the wire gently and smoothly into the molten solder up to the edge of the flux. Be sure not to get any solder under the insulation!

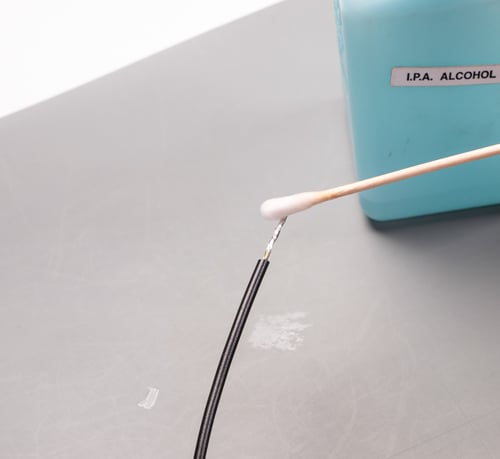

6.Lastly, clean off any excess soldering flux from the wire with an appropriate cleaning agent for the flux that you were using.

It is very important NOT to apply flux or solder too close to the insulation because the flux and solder can wick up the wire and under the insulation in a capillary effect as you dip the wire into the pot.

Any solder under the insulation will cause the wire to become brittle at that point and any flux will welcome potential corrosion.

As you can see, when soldering in electronics, the solder pot has many uses. We touched on one in this article. The FX-305 is one of the fastest heating solder pots in its class and has beneficial features such as built in solder alloy heating profiles, a solder leak detection sensor, safety cover, and much more, allowing you to use the solder pot with precision, ease, and safety.

For additional information, visit us at www.HakkoUSA.com or contact us at 1-800-88-HAKKO (42556) and at [email protected].

-HakkoUSA