We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Why use a Dual Port Soldering Station?

“Two heads are better than one.” This is a phrase that signifies the helpfulness and benefit of having another person think with you, and come up with the best possible solution. The same stands true for soldering and desoldering stations. Why be limited by one soldering iron, when you could use two? But why exactly would anyone ever need to use a dual port soldering station?

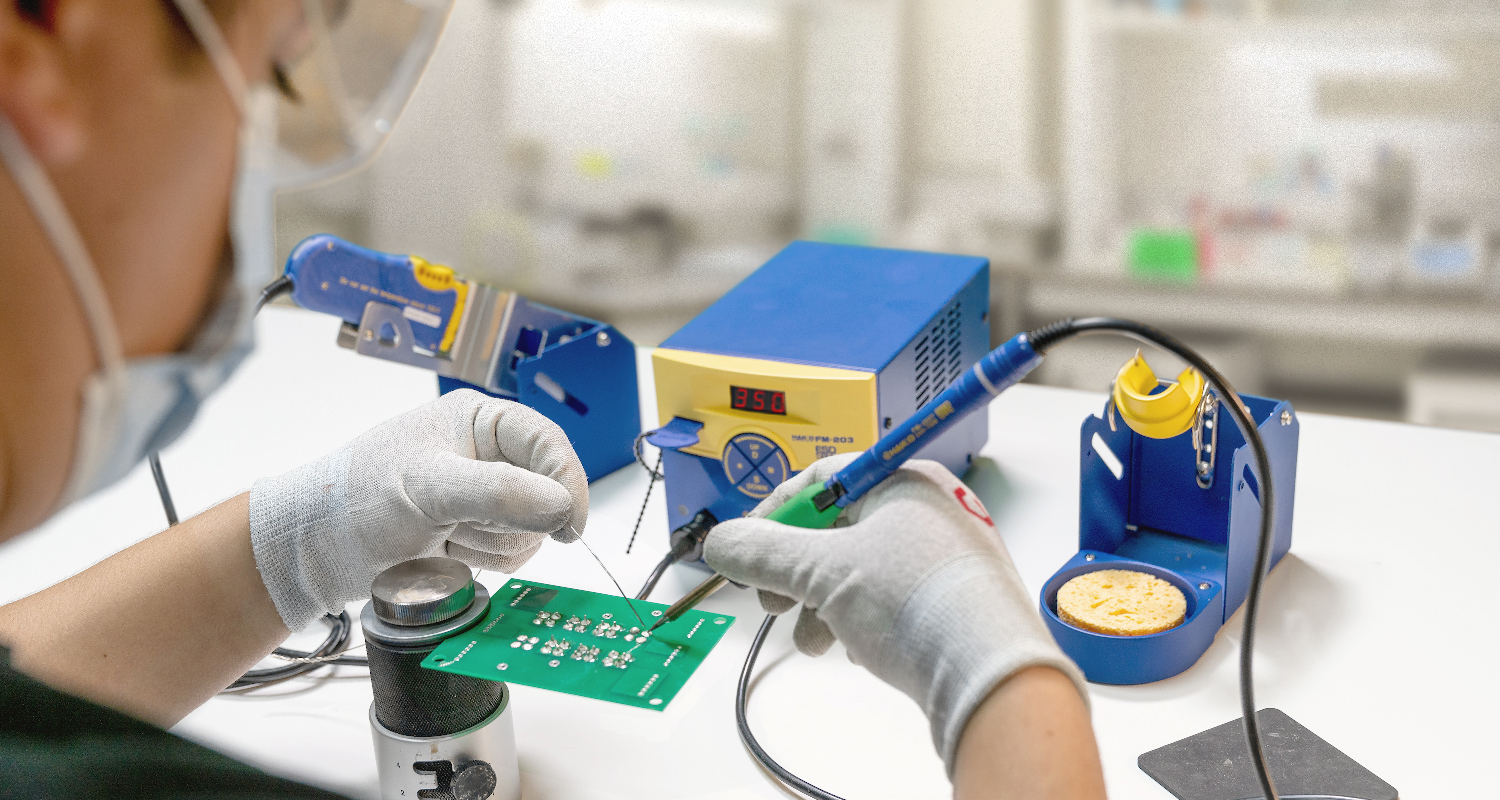

The answer to that question is... convenience and versatility. The Hakko dual port soldering stations can work with a variety of different handpieces, including SMD rework tweezers, Micro soldering irons, and Heavy Duty soldering irons. Since not all components on a PCB are the same, you may need to use tips that are different in shape and size, and also different temperatures, all depending on the application. For example, instead of turning off your soldering iron to exchange the iron tip, or to change the temperature settings, with a dual port soldering station from HAKKO, you can simply pick up the other handpiece connected to the other port/channel which already has the proper temperature settings and correct tip shape installed, and you’re ready to go! This makes your life so much easier!

Even when using a cartridge type tip, you still must pull out the soldering iron tip, insert the next tip, and wait for the iron to heat up again. Even with the heat up times being rather quick due to recent advancements with technology, the ability to switch between handpieces comes in very handy because it allows the operator to continue working without needing to stop, reset, then get back started again. This also gives you the convenience of getting two different tasks done with one station.

Take for example, replacing a DPAK on a PCB. You have two separate leads on one end of the component that are relatively easy to reflow. But you also have the large heatsink terminal on the other end, which make it difficult to remove this type of component with a single soldering iron. Having two irons running simultaneously will allow you to use what some call the “chopstick method” so you can reflow all three points to remove the component but using a tool such as rework tweezers may simplify the process.

The HAKKO FM-203 Dual Port Soldering Station allows usage for parallel removers (FM-2022) and micro-tweezer (FM-2023) handpieces for SMD rework. You can use the parallel tweezers (FM-2022) to remove a component from a PCB, then solder it back onto the PCB using a soldering iron (FM-2027) plugged into the other port/channel, all in one station! The FM-203 works with the standard iron (FM-2027), the micro iron (FM-2032), micro tweezers (FM-2023), parallel removers (FM-2022), and the Heavy-Duty iron (FM-2030). It can also be equipped with the FM-2024 desoldering gun if you have the desoldering module connected to it.

Along with the versatility and convenience, a dual port soldering station may also allow two operators to work off one soldering station. This clears up workbench space and makes great use for an assembly line of operators. Going above and beyond the traditional dual port soldering station is the FM-206, which is a 3-port Rework Station. This 3-port station offers the ability for you to tailor the station to your specific needs with options for soldering, micro soldering, desoldering, rework tweezers, and even a hot air pencil.

The multi-port FM-206 station gives you quick access to multiple handpieces and makes working applications fast and easy. We’ll go over the FM-206 in another article of Hakko Tips. Be on the lookout! That’s all for now, hope you enjoyed the read!

For more information visit us at www.HakkoUSA.com you can contact us at 1-800-88-HAKKO (42556) or email us at [email protected].

-HakkoUSA.