We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

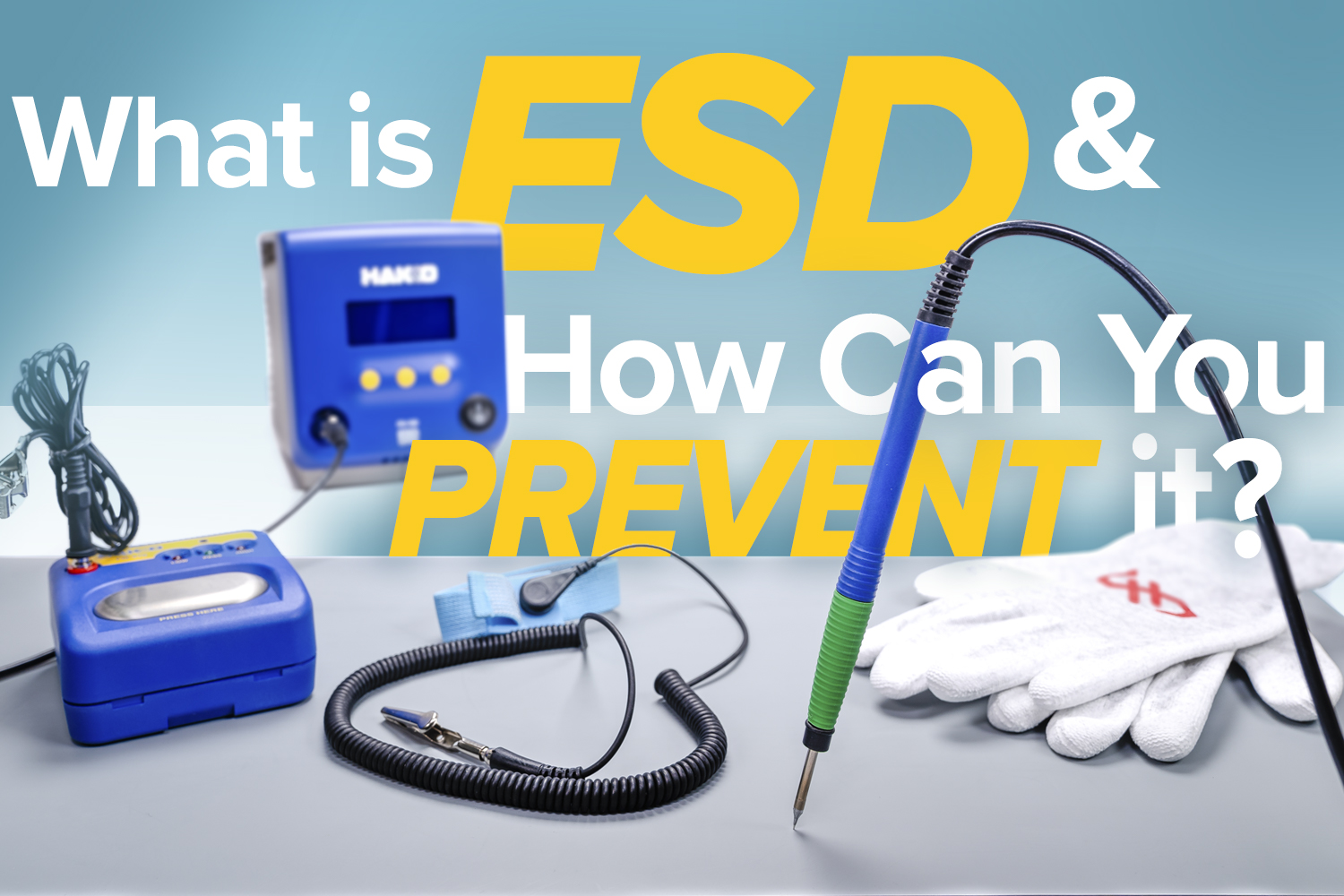

What is ESD, and How Can you Prevent it?

What is ESD? The short answer is electrostatic discharge, but why is this important and what can you do to prevent it? ESD, otherwise known as electrostatic discharge, is the transfer of an electric charge that takes place when two objects that have been charged with different electric potentials or have different electric potentials due to static induction meet one another. Basically, if you’ve ever been shocked by another person or a door handle, that’s ESD transfer.

This electric discharge can cause damage to electrical tools and components and, in some cases actually cause equipment failures. The most frequently occurring damage caused by electrostatic discharge is when a person or tool that is electrically charged touches a grounded device which has a low resistance to static electricity, which in turn causes the sudden flow of electricity between the two objects.

We here at American Hakko Products understand the importance of protecting your electronic devices and components from electrostatic discharge. We have taken the necessary steps to design our Products with ESD control to prevent damage from electrical charges that may occur during the manufacturing process.

ESD prevention within an EPA or (ESD Protected Area) may include using appropriate ESD-safe packing material, Wrist and Ankle straps to prevent high voltages from accumulating on a worker, anti-static mats, conductive flooring materials to conduct harmful electric charges away from the work area, conductive coatings on tools and grounding of the working surface, as well as controlling the humidity levels within the EPA. Where insulative materials cannot be grounded, the use of an Ionizer is recommended, this will help neutralize charged surfaces on insulative materials.

ESD-SAFE labeled Hakko Products are designed for static control and meet industry-required standards:

- The unit is grounded, and the soldering iron tip maintains a tip-to-ground resistance of less than two ohms at any given time.

- The electrical potential between the tip and ground does not exceed two millivolts at any given time.

- ESD safe materials, which have a surface resistivity of less than 1011 ohms/square or pass a static decay test as defined in MIL-STD-3010A TM-4046, are used in the construction of the unit.

There are certain components of your HAKKO product that are EXEMPT from the ESD requirements and are required to be insulative for electrical safety, such as power cords, power switches, power receptacles, fuses, potentiometers, and other similar components.

We hope you found this interesting and that you’ll join us for next month’s HAKKO Tips.

For more information visit www.HakkoUSA.com or contact us at 1-800-88-HAKKO(42556) and at [email protected].

-HAKKOUSA