We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Preheating PCB's During the Rework Process

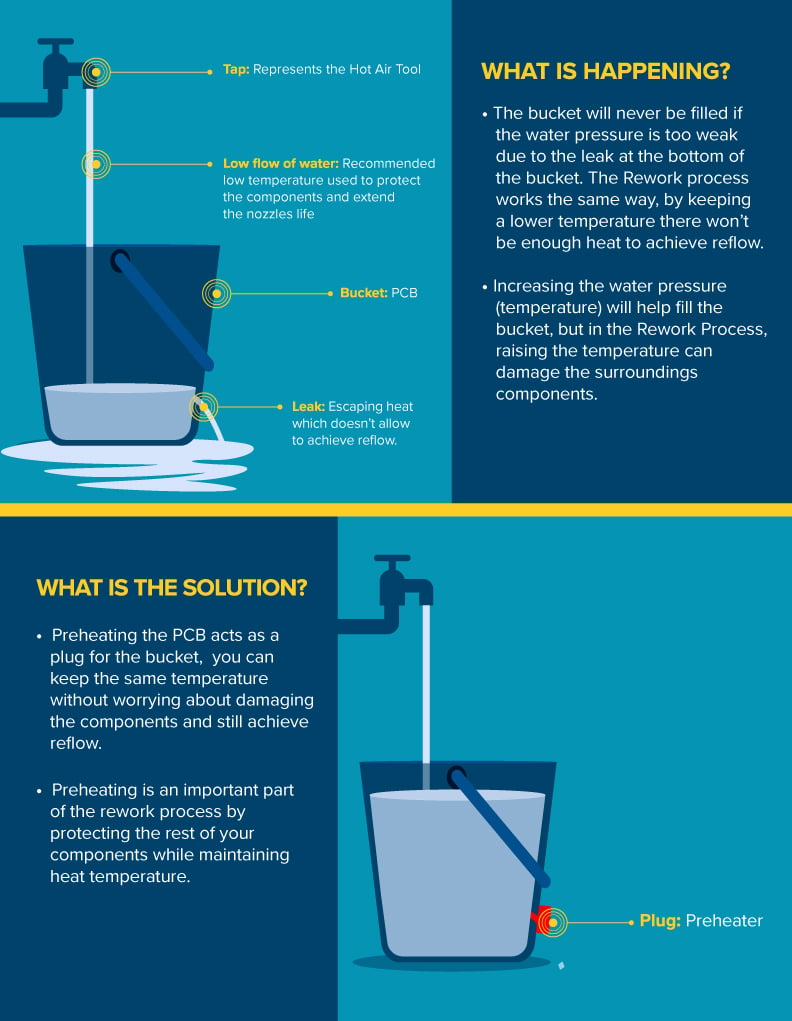

When reworking a PCB, the best method is to replicate the original manufacturing process as closely as possible. This usually involves the use of a hot air tool to reflow the solder connections of the surface mount component. But today’s boards are so well engineered to dissipate heat that using localized heat from your hot air tool just isn’t enough. This would usually require you to need even higher temperatures for the hot air tool, which can cause damage to the surrounding components as well as the target component.

This is why preheating the PCB’s can be an important part of the rework process. Preheating the PCB occurs in the original manufacturing process where the entire board is saturated with heat in a controlled manner, usually ramping from room temperature to a predetermined temperature at a rate of 3°C per second. By doing this, a lower top side temperature can be used on your hot air tool to achieve reflow.

The HAKKO family of preheaters includes the FR-830 which is a hot air preheater that is ideal for very small boards with 4 to 6 layers. The FR-830 preheater provides a small localized preheat area but for larger boards we recommend the FR-870B and FR-872. Boards that are larger, have many layers or heavy layers of copper might require using a larger preheater.

Both the FR-870B and FR-872 include different modes of operation. They include a simple power mode that allows you to set the percentage of power output and a simple thermocouple-controlled mode that uses a closed-loop control system. There’s also an automatic mode for either power or thermocouple, which allows you to replicate the original manufacturing process more closely by creating a stepped preheat profile like the process found on SMT lines.

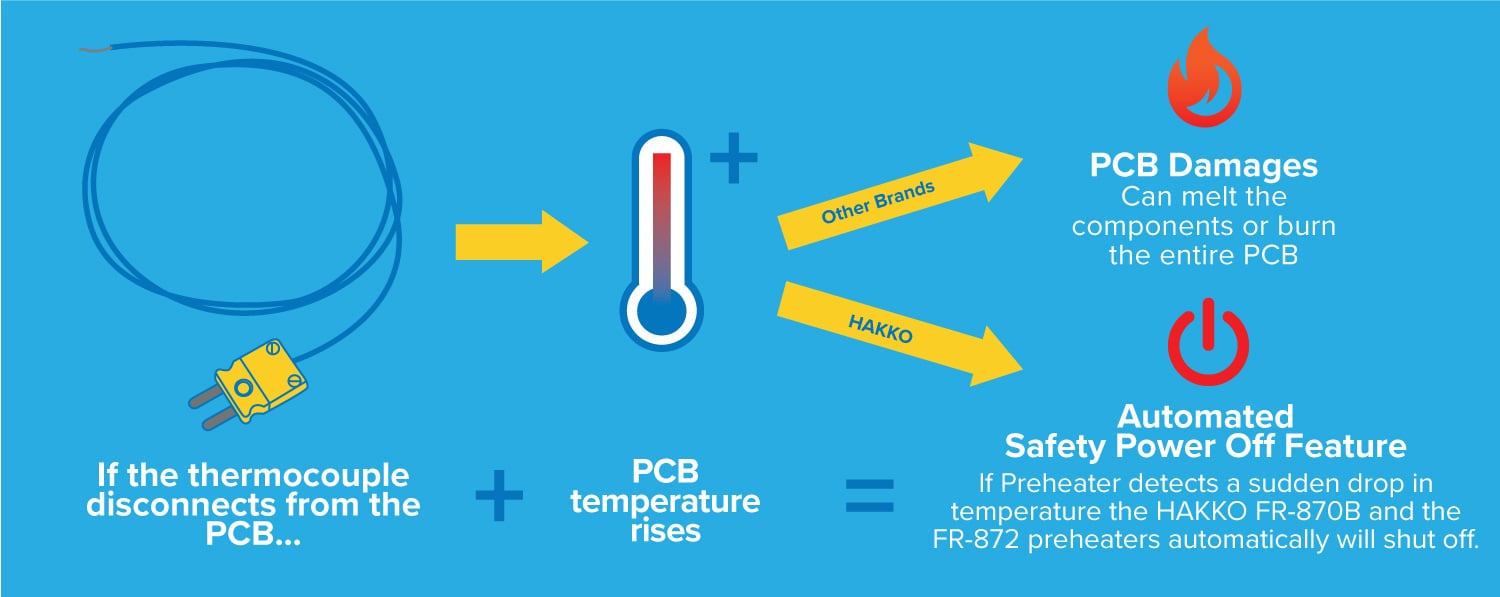

These two preheaters also include special features that allow for a user defined ramp rate when using the thermocouple. Along with this you have an emergency stop feature that monitors the rate of heating of the PCB. This system checks for anomalies, such as a sudden drop in measured temperature due to the thermocouple coming off the PCB during preheat, which will automatically stop the process.

For the ultimate hot air rework system, the HAKKO FR-811 provides the ability to integrate with its own preheater so the entire heating process is not only controlled but coordinated between both units.

For more information visit us at www.HakkoUSA.com or contact us at 1-800-88-HAKKO (42556) or at [email protected].

-HakkoUSA